|

|

#1 |

|

Участник

|

Sumit Potbhare: The Complexity of Operations in Retail Warehousing | Approach to D365 for Commerce with Adv WH Mgmt

Источник: https://sumitnarayanpotbhare.wordpre...h-adv-wh-mgmt/

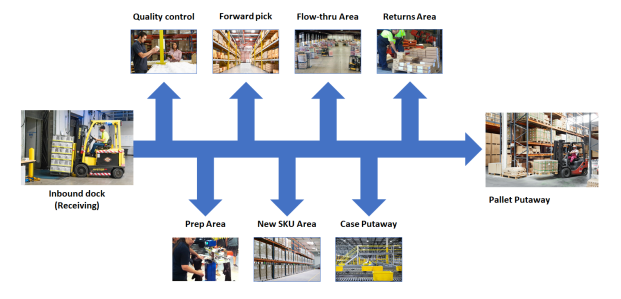

============== Hi guys, In this blog, we are going to understand another key aspect of Retail Warehousing which is the Complexity of Operations. A warehouse can be more than just a place to store products. The competition in Commerce is growing more intense with each passing year. There is a need for something extra that your Retail warehouse offers. You call it special functions or special operations such as Catalogs with special product requirements–product personalization and/or customization, special sizing, etc. These special functions create an opportunity which appears to be significant: A Bain survey of more than 1,000 shoppers found that while less than 10% have tried customization options, 25% to 30% are interested in doing so. While it is hard to gauge the overall potential of customization, if 25% of online sales of footwear were customized, that would equate to a market of $2 billion per year.  Providing the product customizations and personalization may help brands boost their sales but it also involves adding complex functions to their Retail warehouse activity. Let us have a look at such a special function in a Retail warehouse: Garment On Hanger (GOH) (also known in certain circles as Hangtainer). Many Retail warehouses dealing with apparel industries have such kinds of services and they usually benefit in terms of labor, time, and cost by utilizing such operations as they can move the garments from the container to the shop floor DIRECTLY and in a good condition. These are standard/dry containers that are converted/outfitted to be able to safely and conveniently carry garments on hangers – the same way you see them hanging in all the major retail stores. It’s not just the process complexity but the product complexity as well. One more way in which retail’s really unique relative to manufacturing or wholesale distribution is personalization. Personalization allows retailers to customize products for consumers to their specific needs. So you can order a shirt and get your name written on it or glassware and get it monogrammed.  All of them are complex if you think of them from a software perspective because you have to get the information about what needs to be personalized down to the floor, so this operator can actually get it into the shirt.  You also have to think about the situation where you might have an order that doesn’t need personalization but few items in the same order that needs personalization. And so you have to get the items that need personalization married together with the items that don’t. And that creates complexity. All this complexity shows how personalization in retail makes retail more complex than, manufacturing or wholesale. The process complexity of retail can be seen, in each of these different kinds of unique areas that you have inside retail warehouses that you don’t have in wholesale and manufacturing like the personalization area or the prep area. Inbound and Outbound process complexity Another part of the process complexity that you have to deal with when you set up D365 F&O is how do you just get the stuff there? The logic that’s necessary to route things either on the inbound side or the outbound side to these different little areas of specialization is complex. In fact, If you take a look at the more traditional manufacturing or wholesale warehouse when you pull it off the truck, the decision about what needs to happen to it next is pretty simple. But in a retail warehouse, there could be lots of places that the product that’s newly received goes before it’s really ready for sale and ready to be put away.

So the process complexity of a retail warehouse will lead you into questions from the warehouse manager that look like this:

The complexity of retail warehouses is not just the process and routing things but also the products that it has to store and ship. In most manufacturing warehouses, when something comes in, it really doesn’t matter to the guy working on the floor what’s in that box.  But in retail, that’s not so true. You really need to know what’s in that stuff, because it’s going to influence where it needs to go, or at least the system needs to know. And so you need to be able to identify on the product master what kind of stuff this is. Here are a couple of examples,

Pre-pack products Pre-pack products

Non-conveyable product Non-conveyable product

Personalized product Personalized product

Ship alone product Ship alone product

Hazardous product Hazardous product

High-value merchandise High-value merchandise

Different variants SKU’s Different variants SKU’s

Garments on HangerAll of these are examples of how, the product diversity is immense in lots of retailers, and that creates the need for system support to tell the guy what kind of stuff is in this box that I’m moving so that it can get to the right place, or the right thing can be done to it. Garments on HangerAll of these are examples of how, the product diversity is immense in lots of retailers, and that creates the need for system support to tell the guy what kind of stuff is in this box that I’m moving so that it can get to the right place, or the right thing can be done to it.So as a result of all these diverse nature of the operation and the different types of products that a retailer might offer to the consumers or their stores, you are sure to get questions that test you on your understanding of how D365 F&O can address this many different types such as.

I hope this blog helps you in some or the other way in this Retail Journey. Feel free to reach out for any clarifications. If you like my blog posts then comment and subscribe to the blogs. Please follow me on Facebook | Google+ | Twitter | Skype (sumit0417) Enjoy RetailDAXing. Disclaimer: The information in the weblog is provided “AS IS”; with no warranties, and confers no rights. All blog entries and editorial comments are the opinions of the author. Credits: Microsoft Learn, Microsoft Docs Источник: https://sumitnarayanpotbhare.wordpre...h-adv-wh-mgmt/

__________________

Расскажите о новых и интересных блогах по Microsoft Dynamics, напишите личное сообщение администратору. |

|

|

|

|

|